I love spinning and knitting fine wool yarns. And so my recent fascination with lace feels like a natural progression of my interests. I wasn’t quite sure which of the wide range of breeds available to hand spinners would suit lace best. Nor was I quite sure what a lace textile ought to feel like. In this post I’m going to share with you my experience exploring these questions with a commercially prepared Leicester Longwool top: a very longwool.

Warning: I conclude this may be a terrible idea for your end use. Sample and proceed with extreme caution. Otherwise you may produce prickly dense wire.

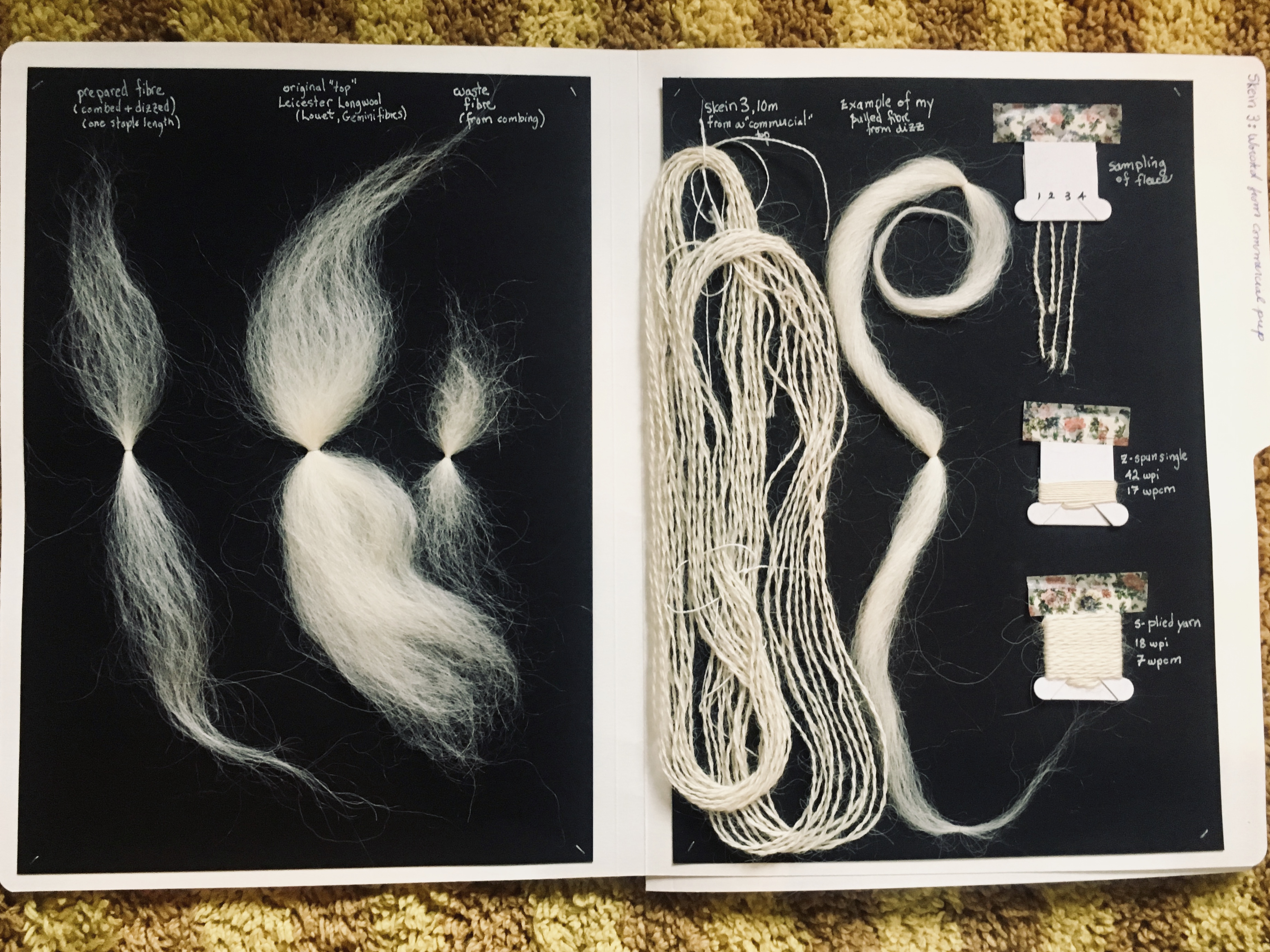

Having moved my life across the ocean last year my fibre stash is quite small. I managed to fit into my suitcase 100g of commercially prepared Leicester Longwool top. I have no clue what possessed me to pack this particular fibre. Perhaps I wanted to practise tackling an 8 inch staple length? Taking a more careful look at the fibre I noticed that it would require a little extra processing as there seemed to be short and long fibres mixed in. Using my fine combs I was able to separate the short and long fibres. Carefully pulling the long fibres from the comb through a button hole (i.e. diz) I made my own top. (On the left: image of the final prepared pulled top and yarn)

Using a short forward draw I made a few ply back tests to see the effect of the yarn diameter on the yarn’s properties.

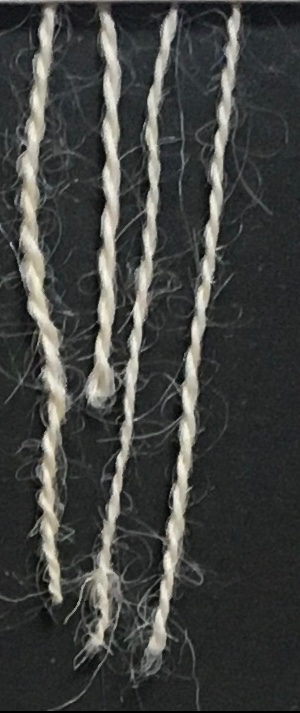

For similar angles of twist (as shown on the left) the yarn became increasingly more wiry. All four yarns were quite dense. Already I am starting to think this might not make a very nice lace-weight yarn for a textile that would be worn near the skin … despite carefully aligning and smoothing the fibres with my pinch there are quite a few prickly fibre ends sticking our from the yarn.

There are many lace traditions both ancient and modern. I am quite ashamed that when I tackled this fibre I truly thought I could produce a lovely Shetland or Estonian style lace shawl. However, these textiles require high elasticity at cobweb weight. These are not characteristics of any yarn I could produce from leicester longwool.

While spinning this particularly long staple I was careful to 1) make sure the twist stayed between my hands never entering the fibre supply, and 2) ensure my fibre supply was manageable (i.e. the top I produced was thin meaning I did not have to draft very much to obtain a reasonably thin single). This fibre was quite coarse and not as slippery as some other longwools can be.

I took a step back and re-evaluated my vision. I have a few flannel dresses from Muji I quite like wearing in winter that have round neck lines. Perhaps I could knit a lace collar? After a quick search on Ravelry I came across the Delikat lace collar designed by Stina Öhman. Perhaps I could swatch and see if this would be an appropriate end use for my yarn? Somehow, rather than knitting a swatch I miscalculated the stitch count and executed the collar in its entirety.

The final product is not what I envisioned. It is a lace necklace with weight to it (the yarn is DENSE). I’m not sure I would refer to it as a lace collar and I don’t think increasing the needle size would have helped significantly.

In conclusion, I have proven to myself very thoroughly that this fibre is too coarse and not flexible enough to produce a lace textile in the form we most commonly think of (e.g. shetland or estonia lace).

The technical details: